Owe Forsberg introduces you to Risk Based Work Selection for shutdown or turnarounds in part 2 of this six part video series. This shutdown technique ensures that you’re working on the right maintenance jobs for your shutdown or turnaround. Learn more about the 6 phases of Shutdown and Turnaround Management.

What is Risk-based Work Selection?

The second phase of an effective Shutdown Turnaround Optimization Process is to decide what maintenance work will be done during the shutdown. This work-list selection defines the scope of work.

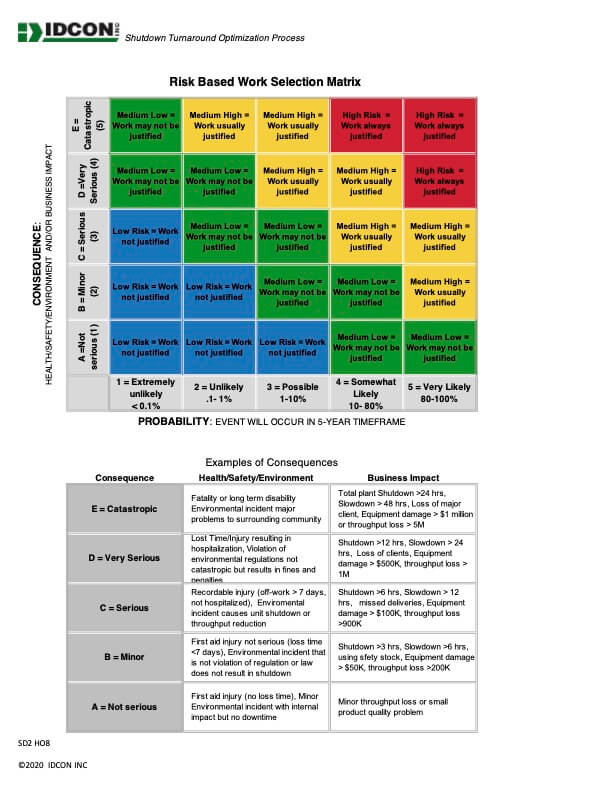

Risk based work selection is an organized and objective process. You calculate consequence of action or condition x the probability of something happening if you don’t do the job. We suggest using a risk-based matrix (see the image below) as a tool to decide what work will be included based on consequences such as health, safety, environmental or business impact x the probability of an event happening in a certain amount of time.

Benefits of risk-based work selection

There are significant benefits of using a risk-based work selection (RBWS) method and matrix such as the one above for your shutdown or turnarounds.

- High-risk work is identified

- Non-value work is eliminated

- The right prioritization of work to be done will aid the planning, scheduling and execution of the work

- Less costly alternatives will be identified – can this work be done without shutdown, etc.

- Identification of work that drives equipment reliability

- You’ll move from a “gut” feeling to a more objective selection based on risk

NOTE: RISK can be subjective based on personal preference of bias. Using a matrix tool and defining consequences and probability allows you to have a process where you pose questions and/or ratings to make the group decisions more objective.

Below is an example of work orders that we use in our Shutdown Turnaround Optimization Training course. To determine if the work needs to be done, you’ll ask key questions and rate the answers based on history and other relevant information.

Work Order: Feedwater pump #4, there is a high vibration reading on drive-end bearing, high priority

Risk based work selection questions to ask:

- Risk assessment of not doing the work? Answer: Not acceptable

- Can the work be deferred to next shutdown? Answer: No

- Can the work be done economically and safely outside of outage? Answer: Yes, execute the work outside the outage. Why? There is a spare pump in place. An approved repair shop is in the region with a two-week repair turnaround.

- Can the work scope be reduced? Answer: No

- Work item to remain in the scope? Answer: No, based on the spare pump and the availability of a repair shop.