Reliability and Maintenance Assessments

Unveil Your Potential

- Find out how good you are

- Discover how good you can be

- Get a clear plan to improve

IDCON Reliability & Maintenance

Assessments Will Help You…

-

Unify operations, maintenance, stores, and engineering

around a clear action plan for improvement -

Strategically prioritize short-term wins and long-term

improvement plans to know how to win -

Form clear organizational goals

to improve your reliability and maintenance

Are you ready for your maintenance assessment?

Improving uptime, lowering maintenance costs, and increasing overall productivity is a goal for most organizations

But if you don’t know the gap between where you are now, and how excellent you could be, it’s hard to make a plan to close that gap.

You can’t make goals. There’s no path toward improvement.

The best you can do is simply “try harder.”

Unfortunately, trying harder won’t take you where you want to go.

You need a clear assessment and a focused implementation plan.

Then you’ll realize your true potential and reach your reliability and maintenance goals.

4 simple steps

To Help You Improve

Equipment reliability

here's how it works

we'll understand your situation

We’ll explore your maintenance management processes and see how we can help you win.

Then create a plan

Together, we’ll create a step-by-step plan. You’ll know where your team needs to go and exactly how to get there.

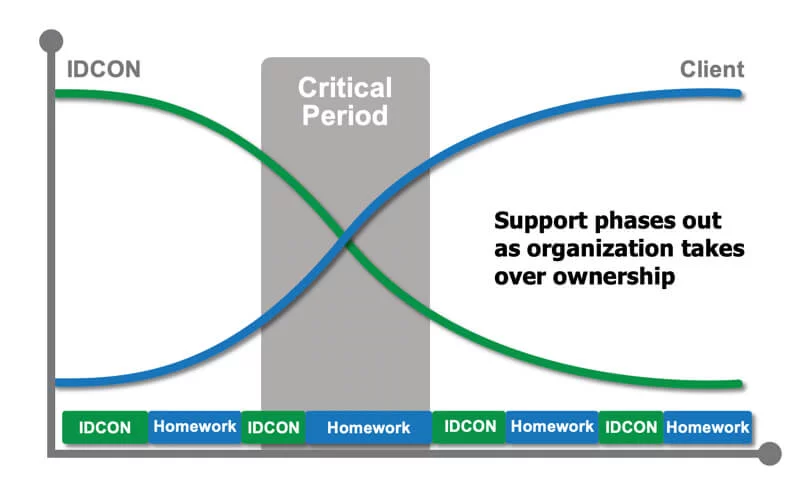

to Implement together

Working on site and with your team, we’ll help you put your plan into action.

So you can REACH YOUR GOALS

Reduce your costs. Increase uptime. Eliminate the hassle of an unreliable plant.

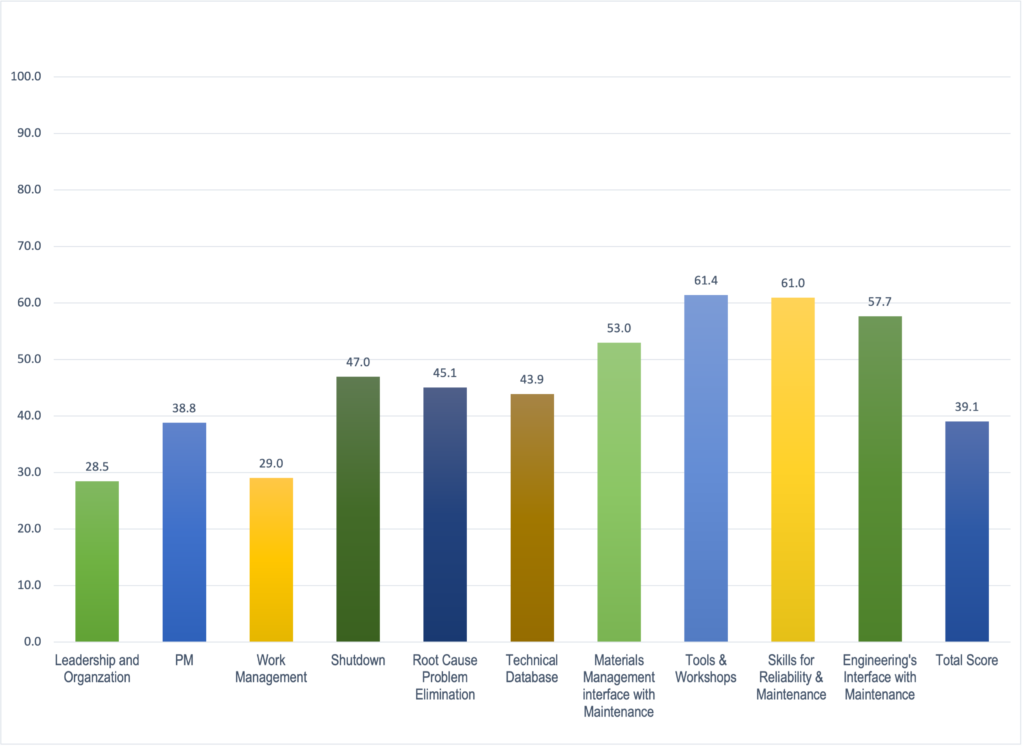

500+ Assessments

Average score across all industries

Average score increase after implementation plan and support

Average increase in uptime

What will 1% improvement mean to your bottom line?

Use this calculation to find out:

OPR = Quality (%) x Speed (%) x Time Availability (%)

It’s time to move forward

-

Unify your entire organization around

compelling improvement goals -

Know where you stand

against other companies in your industry -

Discover simple best-practices

that are often overlooked

Get your free consultation

Talk with a member of our team, today.

See how you and your team can work together to boost your overall reliability.

"*" indicates required fields