If you want to improve production reliability in one or more facilities, it is important to have a clear picture of the reliability goal(s).

At first glance, this may seem as a given, but I suggest that you ask yourself some questions or even perform an informal self-assessment by asking a number of people in your facility. You could also have an objective outside expert perform a formal Current Best Practices assessment.

- Does our facility have an understandable, simple vision of what production reliability is?

- Do we have clear and practical goals for improving production reliability that the employees understand?

- If you ask 10 employees what our goals for production reliability are, will you get similar answers from everyone, including production, maintenance and construction?

- Does the goal have an execution date? Goals without dates are a wish list.

- Is there a plan in place to achieve the reliability goals?

Designing a vision and goals that can be communicated and understood is not easy.

There are many ideas on how it can be accomplished; I can share my own experiences that I’ve seen work. At IDCON, we follow some guidelines when we set up goal images, they are:

- General words in missions eventually must be translated and linked to goals, that way everyone in the organization feels they can contribute

- You must separate goals and activities. A reliability goal may simply be to perform an activity, so it can easily get cluttered.

- Goals should always have an end date and a person responsible.

- It’s good if goals can be measured objectively.

How many production reliability goals should I have?

Our experience is that you should not have more than 2-3 overall goals. These 2-3 production reliability goals are usually identical for ALL organizations that manufacture something. Profit, of course and then, output measured by units produced/ time and cost by total cost/ unit

If you have more than 3 goals, experience has shown us, that you cannot remember what the goals are and you lose focus on what’s important.

For example, if your organization has 7 goals, how do you as an employee know which one is most important? What is the focus?

It is important that production reliability goals fit in with the organization’s overall goals. Hopefully, the overall goals are clear. If they are not, then you can fall back on the goal, which is true for any company, to generate profit for its owners.

For production reliability and maintenance, the long-term goal for most organizations is to:

- Increase production reliability

- Reduce total costs/production unit

Note, in my opinion, maintenance costs/production unit is very uninteresting. Total cost/production unit is a company’s competitiveness.

That’s why in this context we at IDCON stubbornly use the word “production reliability” and not “availability,” since “availability” usually refers to machine availability and ignores other production problems.

Production reliability is a group effort between operation, maintenance and construction.

Goals with the pyramid method

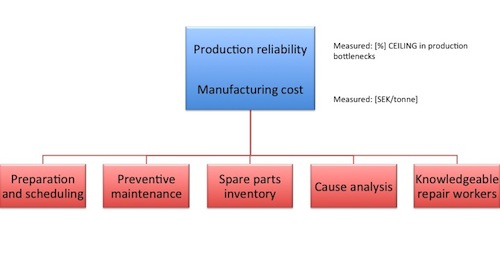

The two goals we use as an example are large goal images. How do we connect these to activities? A pyramid format has worked well for us. It is easiest to explain the concept through an example.

Ask the question: Which processes help us increase production reliability? What do you think will reduce downtime in the factory and reduce long-term costs? Maintenance processes that improve reliability could be:

- Planning and Scheduling (such as: % of break in jobs, for example)

- Preventive maintenance (such as: quality + completion %)

- Spare parts inventory (such as: value + stock-outs %)

- Cause analysis (such as: value of solved problem)

- Knowledgeable repair workers (such as number of recurring problems)

Then we have an image that looks like this:

Image 1. Example of how the first levels of the definition of goal images for production reliability might look.

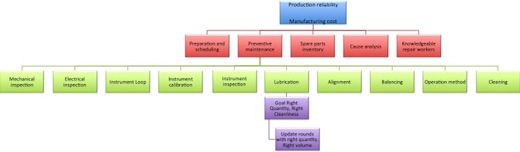

If we continue to take “preventative maintenance” in the image above as an example, PM can be effectively divided into:

- Mechanical inspections (during operation and downtime)

- Electrical inspections (during operation and downtime)

- Instrument loop inspections

- Instrument calibration

- Instrument physical inspection

- Lubrication

- Alignment

- Balancing

- Operation method

- Cleaning

If we continue with, for example, lubrication, a goal could be:

- Goal: All equipment has the right amount and right degree of cleanliness of oil/grease

- Measure: Can be partly measured by analyzing a number of randomly selected bearings and seeing how many have the proper documentation (Quantity, type). Can be subjectively evaluated by evaluating lubricant storage, lubricant tools, filters and logic in the choice of cleanliness requirements.

The image now looks like this:

Reliability goals must be connected to activities and people with deadlines

Each employee probably has a meeting with their manager.

In this conversation, you usually come together on the activities and goals each employee will work on or is responsible for by the execution date.

When we document the activities, the employee is asked to connect the activities in question to the goal image the company has for production reliability.

It takes time to put the system together the first time, but in my experience it gets faster each year and is easy to update, since the higher goals in production reliability and maintenance hardly change, only the 2-3 lower levels change.

By using a simple pyramid, we have now linked an activity, improving documentation of lubrication rounds, to the overall goal of manufacturing costs.

Working method for designing production reliability goals

It is imperative to get buy-in for the goals from the employees One approach that has worked well for me is for management to determine initiatives down to level 2 or 3. In short, management decides what needs to be improved. But you need to allow the employees to work out a proposal for how to do things and propose timelines and exact details of the goals. They develop a proposal for level 4 and down.

Reliability KPIs

This article has discussed goals in general. Often, a goal is measured by using a KPI. Therefore, KPI’s can be developed using the exact same approach. In our lubrication example above, the KPI may be % of equipment that has been reviewed for the correct lubrication. Here’s a great article about which KPIs you should consider and when to start using them.

Leadership in Maintenance Post (1 of