Cutting maintenance cost or improving your results? Which is more important?

If you are a maintenance manager often times you may have heard “We’ll be cutting your maintenance costs (budget)” but you know if you just cut your costs your reliability and performance will suffer. We call this the budget jail.

What’s most important the Cost, the Volume, or the Quality of production?

Is the volume of product you make? The cost of producing the volume? or the quality of the volume you’re producing? All three are important but what order is most important?

In a results-oriented plant they measure quality and volume over costs. By presenting this alternative to being a cost-oriented plant you may be able to convince the accountants that having more quality products to sell is well worth the investment in reliability and maintenance management have higher cost.

Cutting maintenance costs – what tool can you use to show it’s a bad solution to the problem.

Here’s a great resource with a calculation to help you run the numbers. Instead of the typical OEE, IDCON uses OPE or Overall Production Reliability.

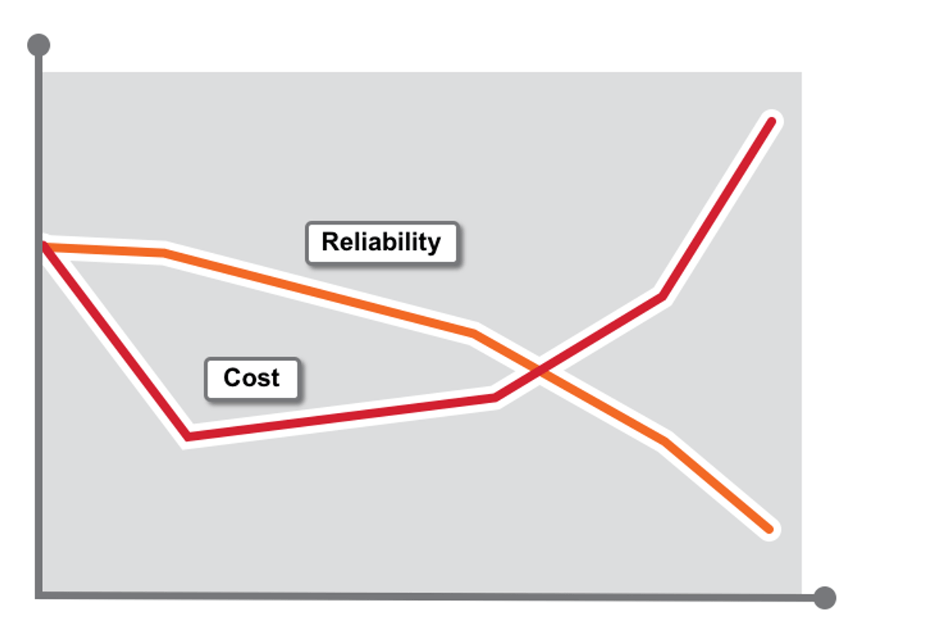

The bottom line is that it is never wise to choose cutting maintenance costs over improving your production reliability. Because what will happen is that costs will come down in the short term but then will rise as equipment failures present due to poor maintenance performance. In many cases, the jobs that suffer in a maintenance cost-cutting scenario are the day-to-day Preventive Maintenance tasks such as condition monitoring and lubrication.

Want more content from IDCON’s resident guru? Pick up copies of his books “Knocking Bolts” and Results Oriented Reliability and Maintenance Management.