Christer Idhammar is a world renowned and awarded Reliability and Maintenance Consultant and Guru. He is the founder and executive vice president with IDCON, INC in Raleigh NC, USA; A reliability and maintenance training and consulting company to Industry worldwide since 1972.

Many organizations take on very good initiatives to improve their maintenance and operations work system and processes such as preventive maintenance and planning and scheduling.

Some achieve good results, but seldom are the results as good as they can be.

Some organizations train their crafts people to upgrade their skills.

Unfortunately, many more organizations do not professionally train their crafts people.

Often if training occurs it is done in bits and pieces by vendors demonstrating new products. A not uncommon idea is that “If we train them, they will leave”. My answer to that statement is “What if you don’t train them and they stay?”

Increasingly we see a shortage of skilled crafts people and many mills have abandoned apprentice programs.

Training of new employees in the maintenance field diverts to “follow Joe training” and this training does not generate the skilled crafts people the industry needs now and increasingly in the future. Joe might only know 70% of what he should know, he will only teach Charlie 70% of what he knows and Charlie will pick up 70% of what he is taught.

One day Charlie will train another new employee. With some simple math it is easy to see that skill levels deteriorate instead of meeting the demand.

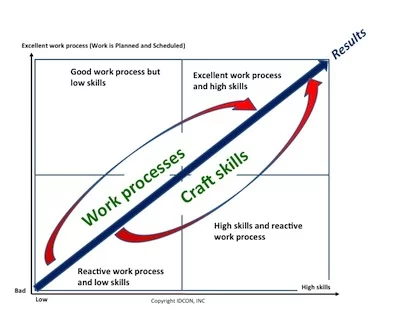

To generate some great results in increased reliability and lower costs both the system people work in and their skills must be improved.

Even with good skills no one can be more efficient than the system they work in allows them to be. A good system instituted in your organization will support the efficient use of your skilled crafts people.

The system will not only help maintain skills, but also continuously improve skills and make it much easier to introduce and upgrade skills of new employees.

The chart below shows that it is important that the system people work in is established prior to investing in professional training of people in maintenance on a precision level.

If you only train people they will not be able to use their skills because the system they work in is too reactive to allow them to use skills such as alignment to a precision level.

If your organization is reactive and your crafts people’s skill level is low your performance is deteriorating. You can upgrade craft people’s skills in a reactive system but this will only lead to minor and not sustainable results.

If the work process is improved you will become less reactive and work will be prevented and better organized but with low skill levels excellent results will be absent. If you improve the work process and upgrade skills excellent sustainable and continuously improving results will be achieved.

In summary: to reach great results you need to both set the system and the process people work in right and then professionally train your craft people. Do that and greatness will follow.

I would like to hear experiences from readers please email me at [email protected] Attn. Christer Idhammar