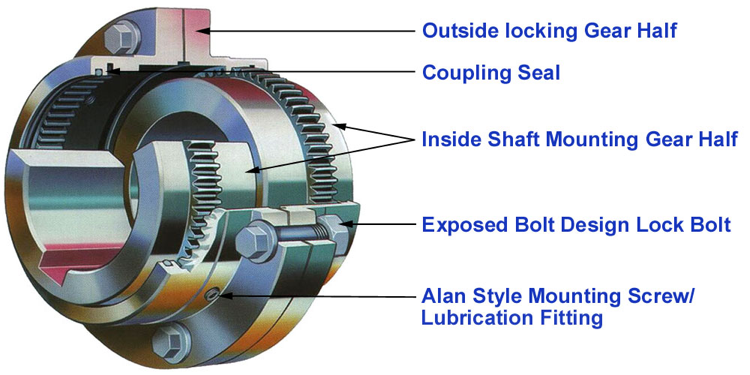

Subjective OTR inspections on gear couplings should include Noise, Visual, Temperature, grease leaking, guards and keyway. Noise could be caused by:

- Misalignment

- Imbalance

- Loose Bolts

- Lack of Lubricant

- Chipped Teeth

Listen for abnormal noise. Wearing/broken coupling may have a high-pitched squeak or rattle.

Do your operators or new Condition Monitoring Technicians need to know the fundamentals of care and inspections?