Why do you need to know how to estimate maintenance work orders?

There are key reasons why estimating work orders is important to the effective management of maintenance.

- Estimating work orders is needed to approve and prioritize the work.

- Allows for more control of the work requested

- Ensures that accurate schedules can be developed with the right resources

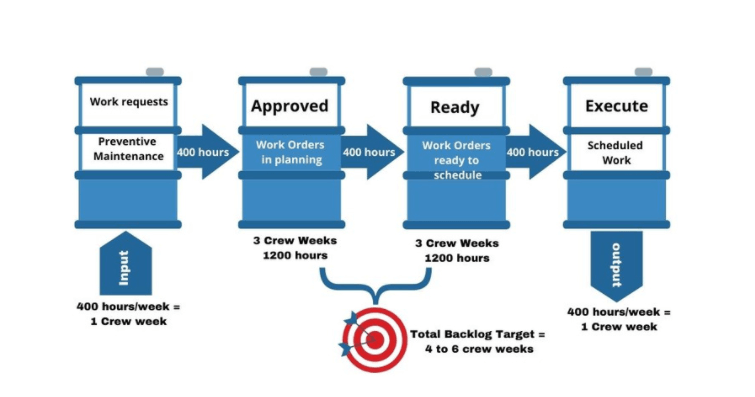

- It helps you manage backlog of maintenance work.

- It improves the relationship between operations and maintenance.

What costs should be included when estimating work orders?

- Labor

- Materials

- Storeroom materials

- Mobile and other equipment, including rental equipment

- Contractors, consultants or trainees (if they will be assigned to the job as an extra person)

What are the steps to estimating?

The 1st pass on estimating is a rough order magnitude estimate of the work requests that go into the unplanned backlog. A skilled planner can do a fast estimate but it does require a visit to the work site where the work request originated. One of your most valuable assets is a planner that can estimate a job correctly.

The next pass is a detailed estimate based on the planned work order. Best performing planner’s estimate should be within +/- 20%

For critical or complex jobs like capital projects, the estimate should be within +/- 10%

How do you know your estimate is right?

A good planner knows to use sources to estimate. They should consult: Historical records, engineer time standards, or compare with others who do the same work. Tapping into your trades and supervisors is also a good way to know if your estimates for work is right. Breaking the job down into small steps and estimating each step will also give good results in estimating the total time. Don’t overlook estimating the handoff and hand back time.

Estimating every work order will improve the effectiveness of how you use your resources resulting in less downtime and improved morale.

Does everyone at your plant understand the value of planning and scheduling? If not, you need a simple but effective way to build this understanding. Learn more about self-paced training.