Great Maintenance Planning & Scheduling

Great Maintenance Planning & Scheduling

A short definition of maintenance planning and scheduling:

Planning decides what, how and time estimate for a job.

Scheduling decides when and who will do the job.

Planning of a job should be done before scheduling a job.

A common initiative after a proper maintenance assessment is to improve these two processes.

But why?

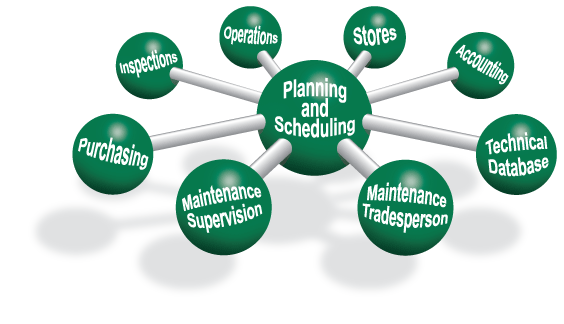

Maintenance planning and scheduling of work orders is the hub of a well functioning maintenance organization.

In order for it to work many other systems need to work well.

Doing regular equipment inspections through preventive maintenance.

Developing a technical database such as a bill of materials, work order history, and standard job plans.

And your maintenance spare part stores must also function well.

How IDCON helps your organization improve:

- On-site classroom training

- Coaching to help you implement what you’ve learned

- On-the-job training

Classroom training is usually effective to increase awareness of good practices, however, in order to achieve sustainable improvement, training must be followed by implementation.

Otherwise, very mediocre results will be achieved.

On-site and on-the-job training, combined with a good condition-based preventive maintenance program AND an up-to-date accessible bill of materials, is the most effective way to enable your people to become more productive.

We work with our clients to make sure our training and coaching are customized to fit their team’s needs.

Learn more

Typical coaching activities include:

- Define or verify existing work processes.

- Make sure all key functions such as planners, supervisors, and operations coordinators have clear roles.

- Set clear priority rules and establish meaning and criteria for existing codes.

- Improve work request usage and clarity.

- Check backlog management and clean up if needed.

- On-the-job planning enhancement for shutdowns (if applicable).

- Shutdown/ Turnaround critique communication.

- On-The-Job planning enhancement for day-to-day work.

- Job package creation.

- Staging areas. Enhance and practice planning and scheduling meetings between operations and maintenance.

- Implement Key Performance indicators (KPI’s).

- Work on effective use of CMMS.

- Hand-on support for history documentation.Improvement of technical database (Bill Of Materials, technical data, equipment identification, etc.)

- Improve integration with materials management

Contractor management and integration of work processes.

We strongly believe that the change process needs buy-in & ownership in the organization.

So, it’s important that a client’s organization takes ownership as soon as possible.

Our role is to act as a catalyst, trainer, and accelerator to coach improvements. Think of us as Yoda to your Luke.

Are you ready? Then request a consultation by clicking the button below to see how we can help.

IDCON offers other training methods in planning and scheduling. We have our public training class and online learning – Click here for more information

Get Free Weekly Reliability & Maintenance Tips

About IDCON

For a manufacturing plant, a halt in production is devastating.

IDCON provides common sense consulting & training so your maintenance team can keep equipment running.

That means less emergencies and more production.

Popular Articles

Want weekly Reliability & Maintenance Tips?

Best practices. Common sense. Pratical tips.

All designed to help you and your team keep your plant running

Want weekly Reliability & Maintenance Tips?

Best practices. Common sense. Pratical tips.

All designed to help you and your team keep your plant running