There are many reasons why many reliability and maintenance management improvement initiatives do not generate the return of investment they can deliver. From my 58 years working in the field of operations and maintenance with many different organizations, I have found some common reasons, which I will share with you throughout this series of articles.

The most common

– Lack of long-term consistent leadership

Per one of IDCON’s surveys on www.idcon.com it shows that over 60 % of plants have had more than three plant managers, production managers and maintenance managers in the last 10 years.

If new key managers introduce a new initiative without truly evaluating present and previous improvements this can often be damaging to progress

The Success of Safety

Best organizations understand that reliability and maintenance improvement initiatives are a process that mostly deals with people and behaviors…it’snot a one-time project. A good comparison is the success many companies have had with improving safety. And just like safety, reliability and maintenance improvement initiatives must be constantly reinforced and measured.

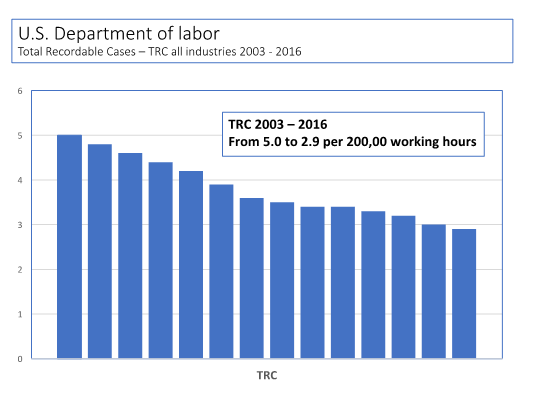

In 1986 the Occupational Safety and Health Administration (OSHA) Total Recordable Cases(TRC) was 8.5 per 100 full time employees for one industrial branch. Today the same industry’s TRC is below 2.

Figure 1 illustrates the same data for all industries in USA between 2003 and 2016.

The TRC is constantly improving because top management has instilled a culture of safety.

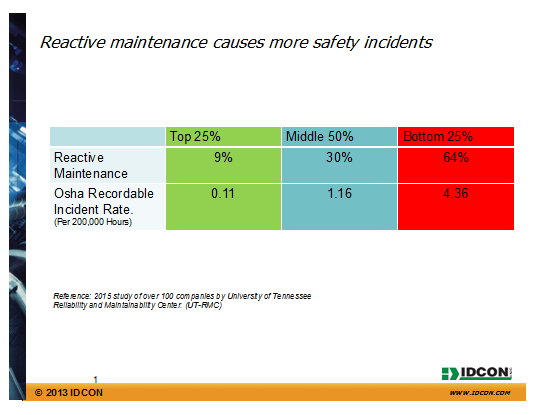

Maintenance practices have also improved with more maintenance work is being planned and scheduled before work is executed. More planned and scheduled work and less reactive maintenance work has a major impact on safety incidents as well as reliable production and costs.

Figure 2 shows that maintenance organizations who reported less reactive maintenance (9%) have a lower Safety Incident Rate at 0.11 than maintenance organizations who reported more reactive maintenance (64%). Their safety incident rate was 4.36.

Imagine the gains in Reliability and Maintenance performance if leadership was as consistent as it has been in the safety initiative.

As always, if you have feedback please contact us at [email protected]

Figure 1: TRC rates ISA 2003-2016

Figure 2: Reactive Maintenance and OSHA incidents