The fundamentals of an effective electrical preventive maintenance program is to reduce the potential for a serious electrical interruption.

The basic rule applying to all electrical apparatus is:

- to keep it CLEAN

- to keep it DRY

- to keep it TIGHT

- to PREVENT FRICTION

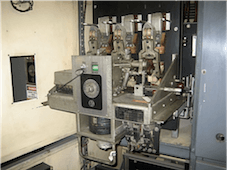

Do you know what to look for when inspecting your Air Circuit Breaker’s Operating Mechanism?

- Inspect for loose, broken, worn, or missing parts (consult manufacturer’s schematics for required parts).

- Examine for excessive wear of moving parts. Observe that operating mechanisms function properly without binding, hanging, or without delayed action.

- Ensure any lubrication is done according to the manufacturer’s specifications.

- Ensure mechanisms are clean, properly lubricated, and all bolts and screws are properly secured. Repair or replace as necessary.