Implementing predictive maintenance practices can be complicated.

Are you experiencing unnecessary equipment repairs that are avoidable and reactive in nature and do you have recurring equipment component failures, such as seals, bearings, and gaskets that are preventable? Do you have failures that make it hard for you to explain your plant’s maintenance expenses (e.g. rotating equipment seizing from lack of lubrication)?

If you answer ‘yes’ to these questions, chances are that you have a problem with your preventative maintenance practices and specifically with the equipment condition monitoring inspections at your plant.

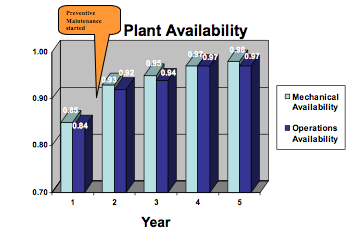

The savings from implementing practical preventative maintenance inspections are significant. Below are results from a plant that started reliability and maintenance preventative maintenance strategies in year 2 which improved the plant’s mechanical availability from 85% to 93%.