Scenario:

You are the Reliability Engineer responsible for developing an in-house condition based PM program. One item you’re monitoring is an important process fan. This fan is located on a large cooling bed for spray-dried materials and is running 24/7.

You decided to have a monthly reading with a vibration data collector and analyze the spectrum. This will take a few months to get started and right now you don’t have the equipment and no one is trained in-house, and it will be some time before you can get a contractor to set up your vibration routes. So, until that happens you decide to check the bearing every 2 weeks with a vibration pen. The overall vibration reading in inch/sec will not give much indication of a bearing condition.

The overall reading from a vibration pen is normally due to:

- Misalignment

- Unbalance

- Looseness

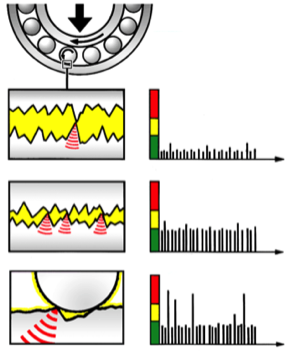

Another available tool is the bearing checker using the shock pulse method (SPM)- see picture below.

In this case you just enter the shaft diameter (inner diameter of the bearing) and the shaft RPM. The bearing checker will display a reading that is green, yellow and red. If the bearing is in the red, plan to replace it. It is a smart idea to have to have the front line operator or maintenance tech to check the bearing condition in when doing their normal PM inspection routes. The SPM signal can also be trended.

Need more essential care and basic inspection technique training or want to train your operators?

Check out our training courses!