The work process we call maintenance planning can always be improved at any mill or plant. The fact is that in most plants we visit maintenance planners don’t plan.

Planners do all kinds of tasks except work order planning.

Typical things planners do but shouldn’t are:

- Act as relief supervisors

- Expedite Materials

- Work on tools

- Plan emergency work

This month’s tip for maintenance planning will help your plant to work in the right direction.

– Build a Maintenance Planning Work flow

- Draw the workflow and agree to it. Work with your operations counterpart, maintenance trades and planners to detail the what, who and how of each task.

Why do we say this workflow must include all involved personnel? Doing so will get buy-in to the process. It will also ensure that the process will be followed and create more accountability across the organization.

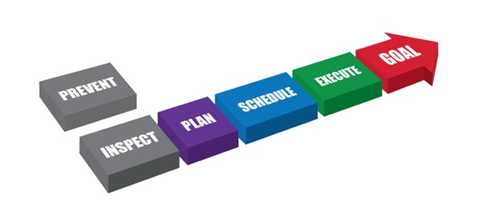

We have provided an example maintenance planning workflow from our manual you can use as a starting point for your effort.

The planning work process does not stand alone!

The planning process is just a piece of our complete planning and scheduling manual we customize to our client’s needs. But identifying it is a very good starting point, your plant can continue the work flow identification in the same format for scheduling, work order initiation, etc.

Notice in the chain that the planning process is separate and distinct from scheduling. In many organizations ,these two interconnected processes become confused. Learn more about the difference between planning & scheduling.

IDCON’s Maintenance planning and scheduling book is the definitive, practical guide you need for success.

IDCON’s Maintenance Planning training & consulting experts are here to support you in your efforts to improve your maintenance planning process.