Leading maintenance in a plant/mine/mill takes a lot of effort. Emergency work comes in a steady stream, some are breakdowns, other work is just “honey-do-jobs.” The workforce needs to be managed, the budget must be met, and equipment reliability must be maintained and hopefully even improved.

The problem in many plants is that there isn’t time to focus on long-term improvements. We are too busy handling the events of the current week, even though we know that most maintenance improvements require long-term initiatives. Even if a plant performs well, there is a danger of becoming complacent with the status quo and not reaching its full potential.

How do you uncover the maintenance and reliability improvements needed?

A good idea is to start with a reliability and maintenance assessment. It helps a team to think about the right things to improve upon and get away from the emergency of today. It will also become the platform for engaging operations, engineering, and spare parts/stores in the improvement process.

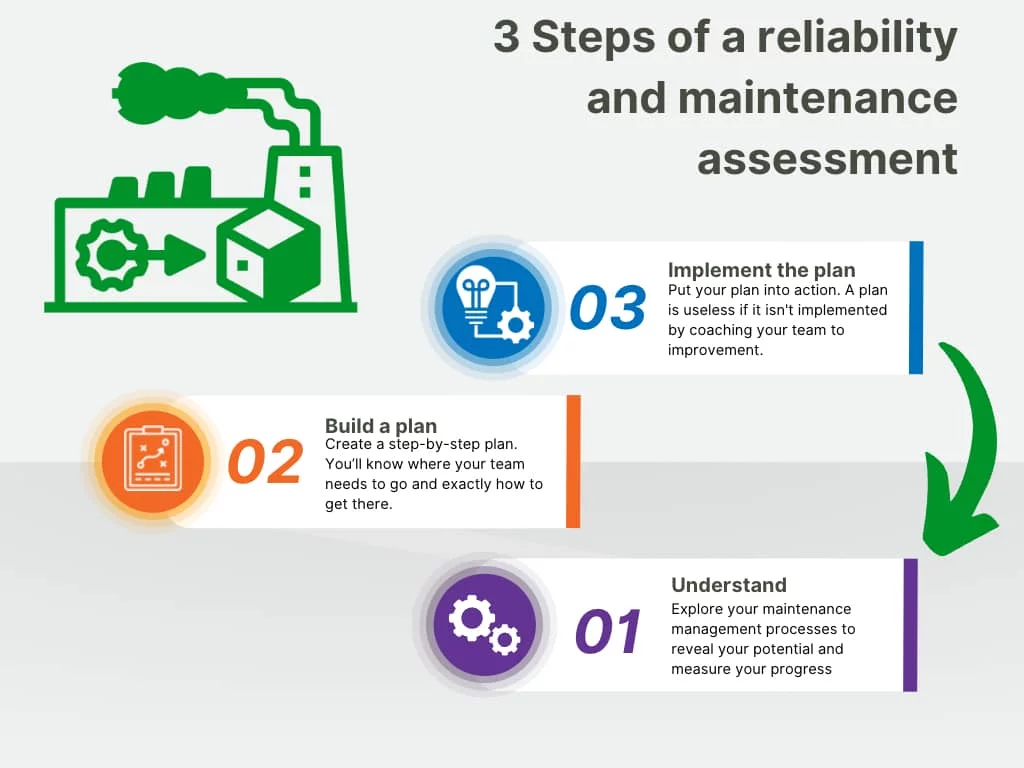

The assessment is the first step in an improvement process. The improvement process can be described in three major steps.

(01) A reliability and maintenance assessment will identify the gap of how good you are versus how good the organization could be

(02) Improvement opportunities are prioritized and becomes the starting point to create goals, KPIs, business case, and an implementation plan.

(03) The implementation itself is clearly the most labor intensive and harder part of the endeavor (but not the focus of this article).

You’ll notice the green arrow in the image below, that’s the Feedback loop: Once the organization has worked on improvements for 12-18 months, a new assessment (01) is conducted and that in turn feeds into an updated implementation plan.

Why do reliability and maintenance assessments?

There are several reasons for doing a reliability and maintenance assessment. Most importantly:

- It helps an organization uncover the gap between how good they are compared with how good they can be. Clearly defining the gaps allows the organization to prioritize the necessary actions to close the gap.

- The assessment should be educational for the organization. Many organizations have an idea of their own gap, but the details are often fuzzy, and most haven’t identified clear actions for how to close the gaps. A reliability and maintenance assessment will make the gaps crystal clear, and the implementation plan will lay out how those gaps can be closed.

- Most people in an organization have ideas around how to improve reliability and maintenance. An assessment is a great tool to help people and departments get together and unify around the same approach.

- Good organizations often struggle to find the next steps towards improvement. A reliability and maintenance assessment can clarify the next steps.

Once there is a clearly defined gap and actions to close that gap, each action must be prioritized and evaluated for the best financial benefit. In maintenance, this can be tricky since many improvement actions provide great long-term value, but often have an increased short-term cost component.

It is therefore recommended to do a business case for the planned improvements. A business case for reliability and maintenance should define the cost of not being reliable, cost to implement improvements, and expected financial gains for reliability improvements. It can be done many ways, but a common way is to calculate what an hour of downtime costs in lost profit for a company.

To make the process into a continuous improvement cycle, the assessment should be redone every 12-18 months, an updated plan should be made, and new implementation efforts should take place

Are there different types of maintenance assessments?

There are many types of maintenance assessments:

- Technical assessment of equipment condition

- IT assessments of maintenance software tools (CMMS) used

- Financial assessments that often solely focus on maintenance cost

- Technical skill assessments of maintenance employees

- Reliability and Maintenance assessments that investigates what drives results

A good reliability and maintenance assessment is designed to investigate what drives better reliability and lower cost. For example, planned and scheduled maintenance jobs will reduce downtime, provide better utilization of resources and improve safety of the work. In an extension this will lead to higher reliability and lower cost. Therefore, it makes sense to assess how well an organization plan and schedule work as part of the audit. This article focuses on assessments that explore what drives better reliability and lower cost.

Problematic reliability and maintenance assessments

If a maintenance assessment only considers current measurable results. As measurable results most companies use the maintenance cost and the reliability of the equipment (measured in OEE or output). Here’s a great article that discusses OEE, and here is another article that explore maintenance cost benchmarking.

There is a huge problem if equipment reliability and maintenance cost is assessed in a vacuum. This is quite common in assessments where maintenance is just a portion of the total assessment. The problem is that both are lagging indicators (results). It measures the results of the past 15-20 years of work and doesn’t tell us a whole lot about the present and the future. Current results are important, but work processes, people’s behavior and equipment quality are leading indicators to those results. It is imperative to look at the leading actions because they will predict future results in reliability and maintenance.

There are similar problems with pure equipment condition assessments. It will give the organization a snapshot of current equipment condition, basically the backlog of maintenance work, but nothing about what processes that need to be in place in order to maintain great equipment condition over time. The organization will only end up with a long list of repair items. However, an equipment condition assessment together with a maintenance work process assessment could provide great results because the organization will get a long-term process improvement plan together with a short-term “fix-it” checklist.

An assessment that solely focus on the use of Computerized Maintenance Management System (CMMS) makes no sense at all. The CMMS is just a database tool to keep track of technical data. The CMMS is an important tool but improving the CMMS will not help the organization improve to any great extent. The change in maintenance and reliability will happen through people and work process improvements.

Skills assessment of trades people is a good idea. However, there is little point in assessing and improving skills if the work processes in the plant are not in place. First, the work processes needs to be in place to create the right environment and time for the craftspeople to use the improved skills.

What is meant by assessing reliability and maintenance “Work Processes”

A reliability and maintenance assessment should unveil if the right work processes are in place and if those work processes will provide future improvements. The work processes are what drives long-term financial improvements through reliability and maintenance. Financial improvements will come through better equipment reliability, then reduced total cost per unit produced.

To clarify, what is meant by “work processes are in place” is that in short, the work processes should be:

- Documented and of high quality, well communicated and understood (Expectation)

- Executed consistently in the field as designed (Execution)

- Followed up on (Follow-up)

The most important of the three requirements above are that the work processes are executed as designed. The other two bullets can be seen as enablers for the execution. A typical maintenance assessment weighting of a work process would be 15% documentation, 70% execution, and 15% follow-up.

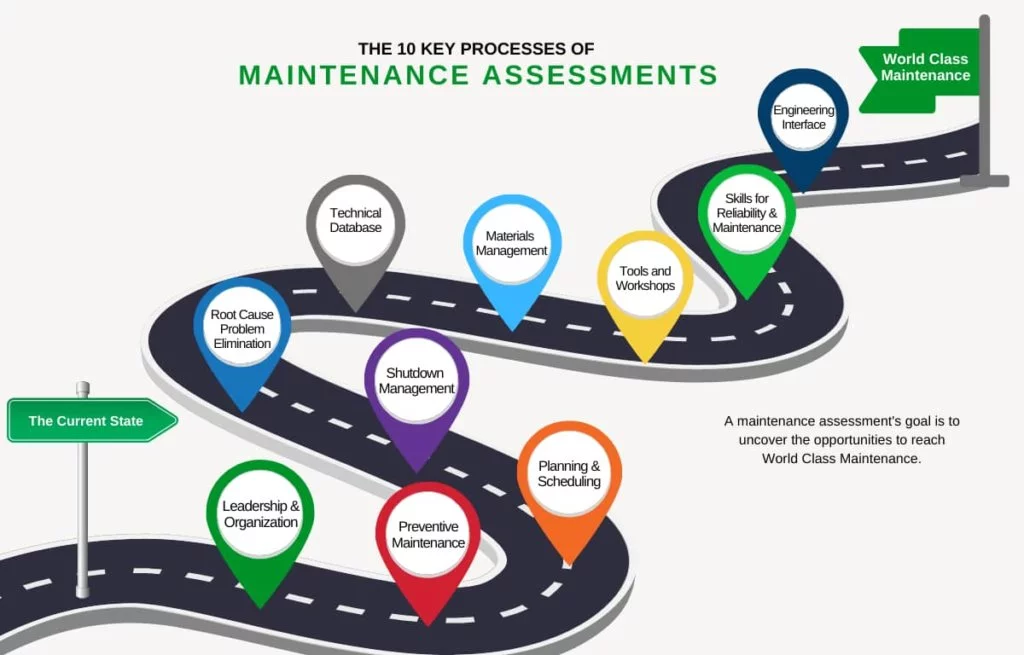

What areas are assessed in a maintenance assessment?

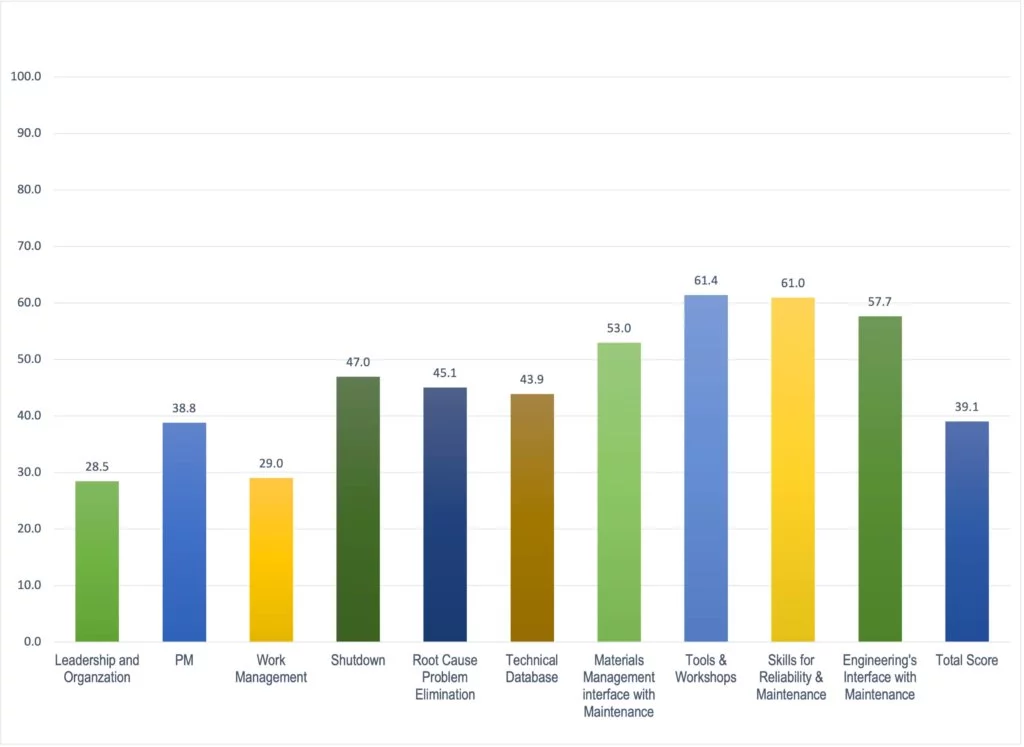

There are many ways to organize a reliability and maintenance assessment. At IDCON, we use 10 key areas to assess. Some processes are key to achieving high equipment reliability and low maintenance cost. Other topics are enablers for the key processes.

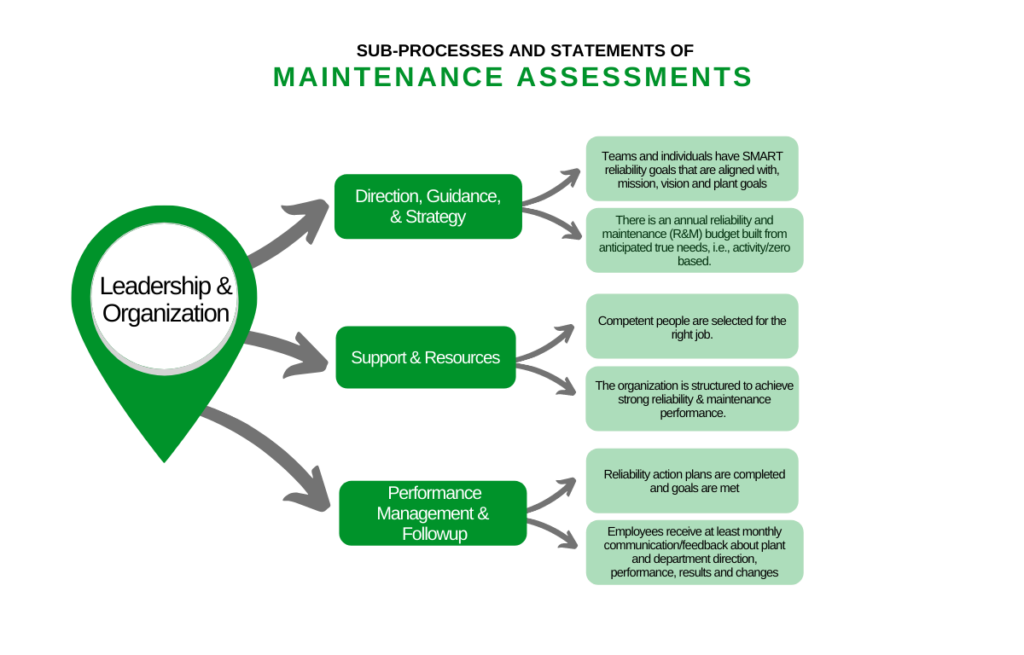

- Leadership and organization for reliability

- Preventive Maintenance Essential Care and Condition Monitoring

- Maintenance Work Management (Maintenance Planning and Scheduling)

- Shutdown/Turnaround Management

- Materials and Spare Parts Management

- Root Cause Problem Elimination (many call it RCPE)

- Engineering’s Interface with Maintenance (design of equipment for reliability)

- Workshops, tools, and facilities

- Technical data for equipment and plant

- Skills of crafts and management

Who should do the reliability and maintenance assessment?

You have two choices as to who will do the assessment.

- Internal assessment team

- External, objective resource

There are obviously pros and cons to both options. Here are the major pros and cons.

Internal Assessment Team:

Pros: There will be engagement and involvement from the internal team, and it forces the team to think through what really goes on in the plant day to day.

Cons: Internal plant people are not typically viewed as experts by the organization being assessed. Their experience from other companies, countries and industries is often very limited. Consequently, they will have a hard time defining what “best in class” means and developing the right tool to do the assessment.

There will be political bias when an internal team is doing an assessment; it’s unavoidable. Finally, the time commitment for in-house resources becomes too large because they are not used to doing assessments and therefore take longer to do them and they have their regular job to attend to.

External, objective resource:

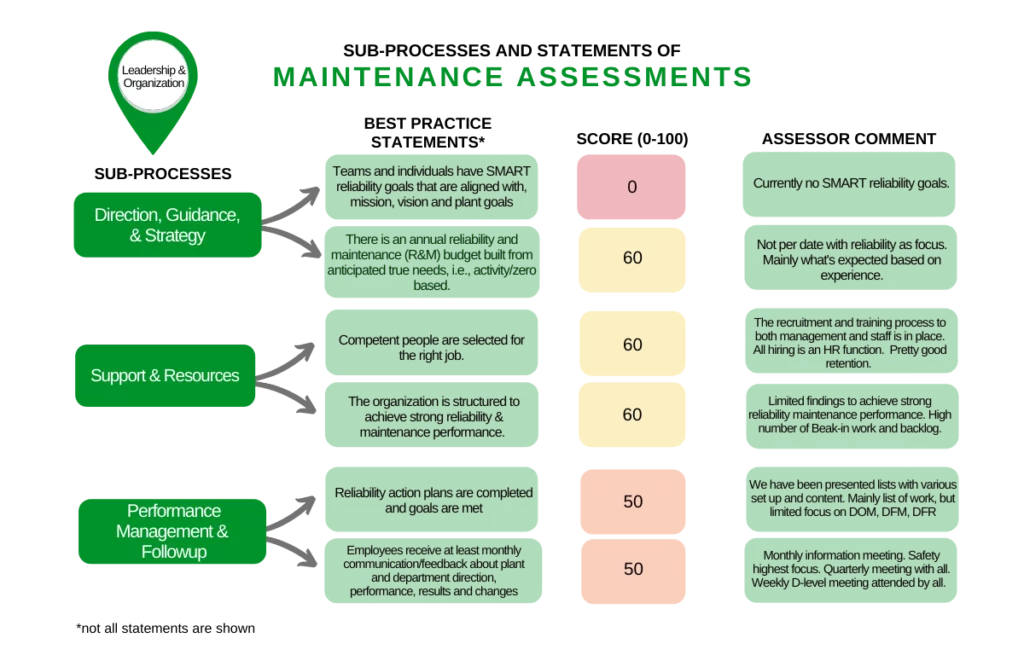

Pros: An external resource, likely a reliability and maintenance management consultant, will have a template for what to assess and a scoring tool to compare the plant with other plants. For example, IDCON’s Current Best Practices assessment has 150 “elements” within the ten key processes (See above). Each element contains a statement that describes the best practice. Each statement is scored 0-100, where 75+ is considered best in class.

They are usually time efficient at executing an assessment since they have done it many times before.

They will be neutral to any plant politics and is more objective.

The external resource should have reliability experience from many industries, different plants in many countries. They can therefore compare the assessed plant to best practice.

Cons: There is a cost to have an external resource. However, one can argue that the internal resources are equally expensive for the total maintenance assessment, but it will not show up as an additional expense.

Beware: It is important that the external resource doesn’t sell equipment, services, and software, if they do there is a risk that the assessment becomes a sales presentation and not an objective review of the processes.

How to do a maintenance assessment

IDCON’s reliability and maintenance assessment method has been proven to be effective for our clients. We’ve even trained clients in the method to perform their own internal assessments¾and some of our clients have even gone on to become certified IDCON assessors.

We are revealing our reliability and maintenance method to you in this article.

- Preparation and desk assessment

- On-site and interview assessment

- Report and presentation of findings and recommendations

- Develop implementation plan together with the plant

Preparation and Desk Assessment

As mentioned earlier, a work process is something that is documented, executed and followed-up on. In the preparation, documentation is collected from the organization. The documents allow the assessor to do a desk review of the documentation before the visit. Typically, the organization should provide around 60-70 documents. Examples of documents should include Reliability and maintenance goals, alignment standards, lubrication standards, role descriptions, workflows for daily maintenance work, inspection routes, work order examples and much more.

The assessor must be able to gauge the documentation quality. These documents are the standard that the organization is asked to perform. We’ve done hundreds of maintenance assessments and have found that documents are missing, not used, or of poor quality. In some instances, standards are set verbally in the plant, but not documented.

The desk assessment doesn’t come close to providing a complete picture, but it gives the assessor clues about whether the expectations for the organization are defined, and about the quality of technical guidance documentation.

On-site and Interview Assessment

The on-site portion of the assessment reviews all aspects of the work process but should center around the execution of the processes.

As a best practice, the on-site assessment should begin with a presentation from the assessors. The presentation should introduce the assessing team, what they are there to do, and the approach. That way each interview doesn’t have to start with an explanation who the assessors are, and false rumors don’t start around the visiting team (like they are here to fire us, etc.).

Best Practices education during reliability and maintenance assessments

In addition to introducing the assessors and what the assessment is trying to accomplish, the introduction session should be educational. It should describe best practices in reliability and maintenance.

This is an important step that shouldn’t be skipped. Why? The assessment goal is to identify the gaps between best practice and the plant’s current performance. If the organization doesn’t have a good idea what best practices are, it will be hard to understand the scoring and what the assessor means by best practices.

The introduction session typically concludes with a self-assessment for the attendees. They rate themselves with regards how good they are at executing key reliability and maintenance processes such as work management, lubrication, shutdown management etc. The exercise gives the assessors an idea of the plant’s self-awareness and understanding for the need to improve. In many cases, you’ll find that some attendees’ perception is far from reality while others are spot on.

One-on-one and group interviews with key employees are the core of the assessment, along with detailed field tours. The point is to observe and understand how the organization executes reliability and maintenance. The assessor will compare and cross-reference the information collected in the interviews with field observations. This exercise requires a lot of experience.

The assessor must be a skilled interviewer who is able to ask open-ended, not closed, questions. For example, an assessor may ask the open-ended question, “tell me how work is completed from when someone finds a problem until it is fixed” instead of “do you plan and schedule work?”. The assessor also needs to have good knowledge of what to look for in the field and be able to analyze all the information and translate that information into an assessment of the gap.

Interviews provide a description from the interviewee, and that description can be compared with other testaments. It can also be verified in the field by attending morning meetings and observing how craftspeople work in the field. For example, do they have parts, tools, instructions on how to do the job, are they able to close work orders, etc. The mix of field checks, the documentation, interviews with different levels and positions of the organization, and investigation of the follow-up system will provide a clear picture of how well a process is executed.

Reporting and presenting assessment finding and recommendations

The assessing team will write a report that contains the gap analysis including a score, findings, and recommendations. The report should also be presented verbally to avoid any misunderstandings.

IDCON’s reliability and maintenance assessment has ten (10) key processes, and a total of around 150 elements, or statements within the key processes. Each statement will be scored and commented on.

The score can be compared to other plants in the same industry or across industries. The most important thing is not the score, but rather whether an improvement can be made or not.

Which reliability and maintenance process to improve first?

The tough thing is to evaluate is which gap the organization should close first. It may not be the lowest scoring best practice. Some tasks are dependent on other tasks, some are more important than others, some are easy to execute, and some are very hard. The assessor’s recommendations are based on their knowledge and experience. Again, it should be noted that the assessor really needs to have experience in improvement projects, not just maintenance in general. As a rule of thumb, an assessor should have a minimum experience from 10 plants in 3 industries, preferably in a couple of countries, to be more familiar with and sensitive to cultural differences and attitudes, and to have seen best practices firsthand.

Without extensive experience, the assessor can’t compare the plant’s performance relative to other plants. There will also be an issue of trust that the assessor really knows what they are talking about. This is one of the negatives for using any assessor who does not have deep experience conducting maintenance assessments across many industries.

Develop implementation plan together with the plant

Some ask the assessor to develop an implementation plan and deliver it to the plant. This is not a bad start, but it will not be enough to make the plan practical to execute. The main reason is that the assessor can’t assign resources to tasks, reorganize the plant (if needed), and commit to executing the tasks.

An experienced assessor can recommend tasks to close the identified gap. However, the plant will have to make decisions regarding implementation pace, assign resources, make possible adjustments in the organization, etc. For example, if preventive maintenance tasks need to be better documented, the assessor may recommend training and a team made up of a mechanic, an electrician, and an instrument tech part time for 6 months to complete the task. But obviously, the plant must agree to the recommendation, assign resources, and decide the pace. Perhaps it is full time for 3 months instead of part time for 6 months?

Typically, a 1 to 3-day workshop can work out the first 3-6 months of the implementation plan.

Implementation after the Reliability & Maintenance Assessment

The implementation is not part of the assessment, but it is obviously the next step. A plan without implementation is just a wish list.

As we all know, implementing improved reliability is the hardest and most time-consuming step. The implementation actions will be different in different organizations since they are all operating differently, with different performance and different equipment and history. The implementation actions will be based on the gap for each plant and often each area within the plant.

Most organizations struggle with the implementation, not because they don’t know what to do, but rather due to the effort it takes. Common excuses for not improving are that there aren’t enough resources, not enough time, and too much cost. But trying and fixing systems early on will reduce effort down the road. So, there is a temporary increase in effort, but the rewards will come in the form of increased reliability and eventually lower cost.

Summary of reliability and maintenance assessments

Here are your key takeaways about maintenance assessments:

An assessment is the first step in an improvement initiative consisting of:

- A maintenance assessment using an objective tool and experienced assessors

- An action plan to address gaps

- Implementing the plan

Maintenance assessments should:

- Identifying the gap between how good you are and how good you can be

- Educating the plant

- Unifying the plant

- Giving new ideas for improvement

There are different types of maintenance assessments. An assessment should focus on what drives the results¾not only on tools, software, or results alone.

A maintenance assessment is best done by a third party, but it can also be done in-house. There are pros and cons to both approaches.

Maintenance assessments steps include:

- Detailed Preparation and desk audit

- On-site assessment

- Exit presentation and Report including findings, recommendations, and a comparative score

A maintenance assessment must be followed by:

- An action plan to close gaps

- Implementation of the plan

Without these two actions, the assessment just becomes a report filed away in a dusty cabinet or on your server.

Contact us today to schedule your maintenance assessment and unveil your potential.

Want to save or share this article? Download this guide below.