Should Every Organization have a Maintenance Supervisor?

We like to say that a good Maintenance Supervisor will work themselves out of their own job. The idea is to have the crew trained so well that they can really make it on their own, but, turnover happens, new people come in, and the Supervisor needs to be there to be the coach.

Despite beliefs that self-governing teams can work, we at IDCON believes this role s necessary because for a variety of reasons, not everyone on the team will always be up to speed at the same time, so having someone always there to take leadership when necessary is vital.

At the end of the day, a good Maintenance Supervisor is a good coach working towards the main goal: work execution. They play an important role in maintaining good Reliability and Maintenance in any organization.

Let’s review, we have gone over their responsibility to screen work orders with the Operations-Maintenance Coordinator (OMC) and to schedule the crew for weekly work, and now we will discuss weekly scheduling meetings, day-to-day responsibilities, long-term goals, and managing the crew. In the end, we will discuss the importance of a Maintenance Supervisor in every organization.

Scheduling duties of supervisors

Weekly Scheduling Meetings

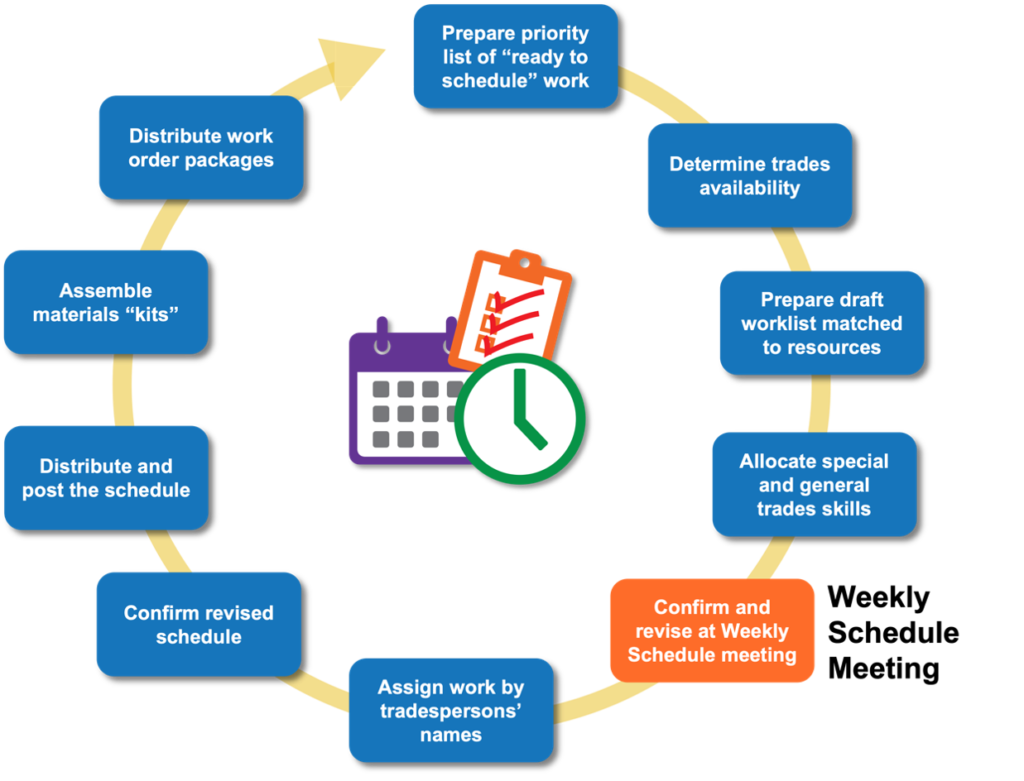

It is best practice to hold a scheduling meeting every week so that everyone is always on the same page. The Maintenance Supervisor should prepare a draft schedule to be agreed upon with, for example, the OMC, the Maintenance Planner, and the Operations Supervisor.

They should track the weekly schedule every day and update as needed based on the work that has been completed. If there is work that still needs to be done, the schedule can then be adjusted to accommodate it.

Day-to-Day Responsibilities

Apart from the Weekly Scheduling Meetings, supervisors are responsible for handing out work packages each morning and making sure the crew is equipped with the correct tools.

They need to follow up on daily work and perform quality checks. Quality checks are important to ensure that the job is being done correctly and meeting the expectations of whoever ordered the job.

Long term goals for Maintenance Supervisors

An important goal they should do is to develop and train their team, along with hiring the right people for the job. Another goal is maintaining a safe work environment for the crew.

They should bring up safety topics during every morning meeting before work starts, and the crew should know to report any safety incidents to them. Every individual is ultimately in charge of their own safety, but they should always be looking out for their crew. Bring in the Safety Manager if there are issues or procedures that need to be improved.

Improving PMs and working on Root Cause with Reliability Engineers is something they should always focus on. Supervisors can often have a better idea of where the problems are in the process so should work with the Engineers to develop strategies for improvement.

How many crew members should a supervisor manage?

How many crew members should a supervisor manage? This is going to depend on how well-trained the craftspeople are and if good processes (Work Management Planning and Scheduling, Preventive Maintenance, etc.) are in place in the organization. In a situation like this, a supervisor could manage up to 20 people at a time.

However, if processes are not in place and skills aren’t where they need to be, it is advisable to keep the number down to 8 to 10 until training can take place and processes can be improved.